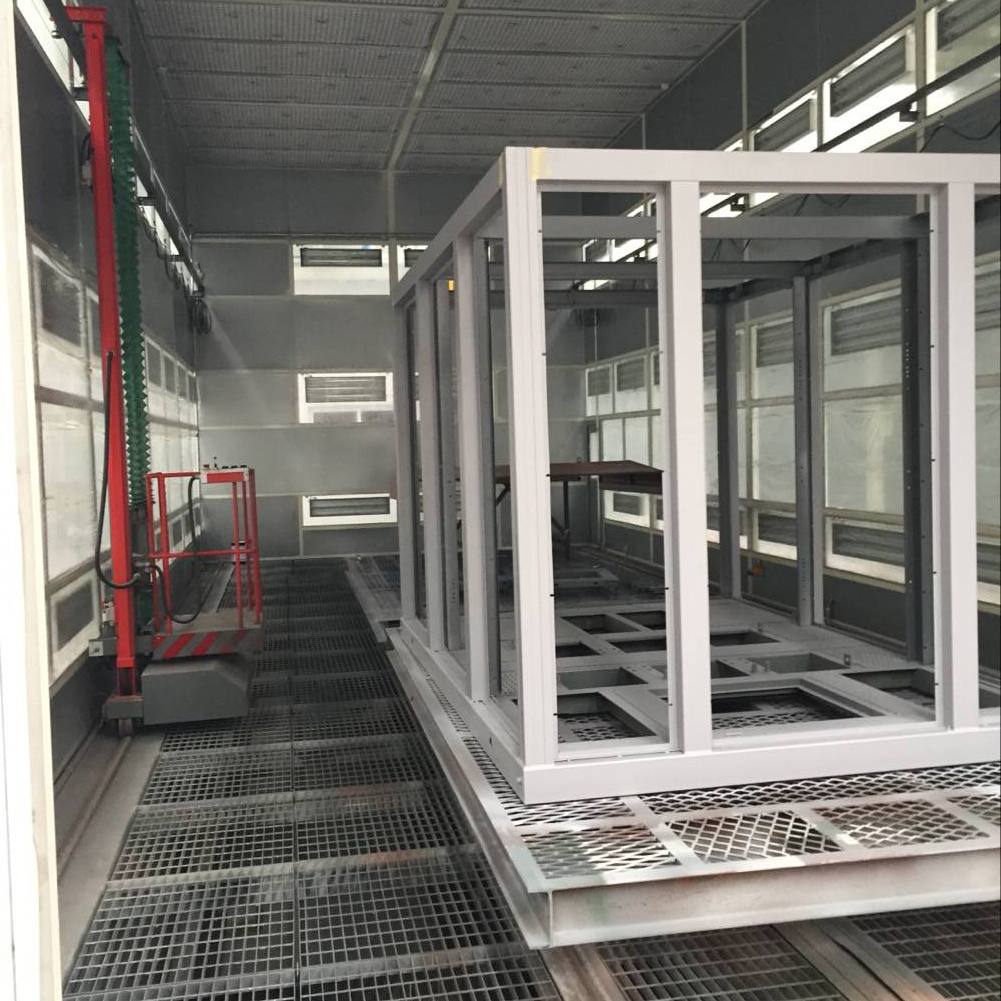

The spray room is an essential equipment for passenger car testing, which helps to confirm the watertightness of the workpiece of the whole vehicle. The device helps make the car's shower test conditions similar to natural rainfall conditions. Use the Shower test booth in the professional inspection of passenger cars to ensure that the car meets the quality standards and does not leak.

The main function of the shower room is to test the watertightness of the car, which is a crucial link in the production process. Any water leak can cause serious damage to the vehicle or its components and be costly to repair. Therefore, the use of spray chamber test chambers in modern automotive production is crucial as manufacturers minimize the risk of water damage to their products.

One of the benefits of using a shower test booth is that it provides a controlled testing environment, which is crucial in identifying leaks or water infiltration in a car. The use of this stand allows manufacturers to simulate real-world conditions for watertightness testing, allowing them to identify and correct problems at an early stage in the production process.

The Shower test booth is also essential, and silicone is used to waterproof the parts of the car that may leak. This helps prevent water leaks and ensures the durability of the vehicle. Silicone waterproofing is particularly beneficial in areas where there may be an increased risk of water penetration, such as doors, skylights and other susceptible areas.

It is also worth noting that the use of shower cabin testing in passenger car professional testing is a cost-effective solution for water leak identification. The device enables manufacturers to test a large number of vehicles simultaneously, making the process faster and more efficient than other testing methods.

To sum up, the role of the shower room in the professional inspection of passenger cars cannot be overemphasized. This is critical in ensuring automotive workpieces are watertight, protected from damage and ensure durability. The equipment is also cost-effective, making it a valuable asset in modern car production.

Manufacturers should continue to invest in shower test stands and other similar equipment to ensure the quality of their products and meet increasingly stringent industry standards. Additionally, regular maintenance and calibration of the Shower test booth is critical to maintaining its efficiency and ensuring accurate results.

Post time: Apr-13-2023