Why is BYD blade battery now a hot topic

BYD's "blade battery", which has been hotly debated in the industry for a long time, has finally unveiled its true appearance.

Perhaps recently many people have been hearing the word "blade battery", but perhaps not very familiar with it, so today we will explain the "blade battery" in details.

Who first proposed the blade battery

BYD Chairman Wang Chuanfu announced that BYD "blade battery" (a new generation of lithium iron phosphate batteries) will start mass production in Chongqing factory in March this year, and in June listed in the Han EV The first time to carry. Then BYD once again hit the headlines of the automotive and even financial sections of major news media platforms.

Why Blade Battery

The blade battery is released by BYD on March 29, 2020. Its full name is blade type lithium iron phosphate battery, also known as "super lithium iron phosphate battery". The battery uses lithium iron phosphate technology, will first be equipped with the BYD "Han" model.

In fact, the "blade battery" is a new generation of lithium iron phosphate battery recently released by BYD, in fact, BYD has been focused on the development of "super lithium iron phosphate" through many years of research , perhaps the manufacturer hopes that through a sharp and relatively figurative name, to get more attention and influence.

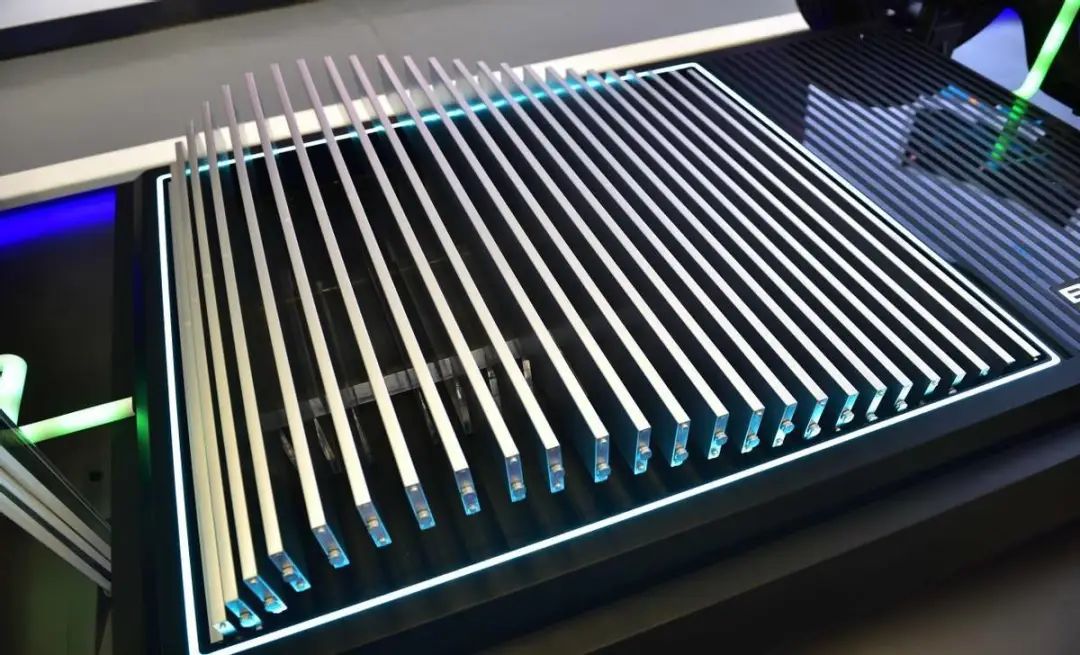

Blade battery structure diagram

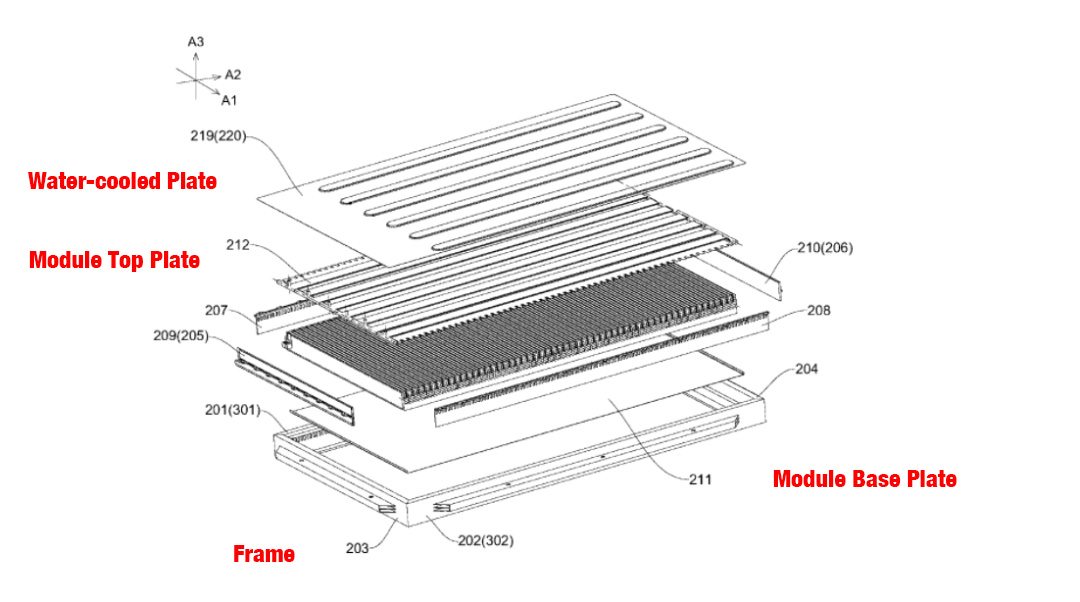

Compared with BYD's previous lithium iron phosphate battery, the key of "blade battery" is made without the module, directly integrated into the battery pack (i.e. CTP technology), thereby significantly improving the integration efficiency.

But in fact, BYD is not the first manufacturer to use CPT technology. As the world's largest installed power battery manufacturer, Ningde Times used CPT technology before BYD. in September 2019, Ningde Times demonstrated this technology in the Frankfurt Motor Show.

Tesla, Ningde Times, BYD and Hive Energy, have started to develop and announced that they will mass produce CTP-related products, and module-less power battery packs are becoming the mainstream technology route.

Traditional ternary lithium battery pack

The so-called module, is part of the relevant parts constitute a module, can also be understood as a concept of parts assembly. In this field of battery pack, a number of cells, conductive rows, sampling units and some necessary structural support components are integrated together to form a module, also called a module.

Ningde Times CPT battery pack

The CPT (cell to pack) is the direct integration of cells into a battery pack. Due to the elimination of the battery module assembly link, the number of battery pack parts is reduced by 40%, the volume utilization rate of CTP battery pack is increased by 15%-20%, and the production efficiency is increased by 50%, which significantly reduces the manufacturing cost of power battery.

How about the cost of the blade battery

Speaking of cost, lithium iron phosphate battery itself does not use rare metals such as cobalt, the cost is its advantage. It is understood that the 2019 ternary lithium battery cell market offer at about 900 RMB / kW-h, while the offer of lithium iron phosphate battery cells at about 700 RMB / kW-h, on the future will be listed Han for example, its range can reach 605km, the battery pack is predicted to be more than 80kW-h, the use of lithium iron phosphate batteries can be at least 16,000 RMB(2355.3 USD) cheaper. Imagine another domestic new energy vehicle with the same price and range as BYD Han, the battery pack alone has a price advantage of 20,000 RMB(2944.16 USD), so it is clear which is stronger or weaker.

In the future, BYD Han EV has two versions: single-motor version with 163kW power, 330N-m peak torque and 605km NEDC range; dual-motor version with 200kW power, 350N-m maximum torque and 550km NEDC range.

On August 12, it is reported that, BYD's blade battery has been delivered to Tesla's Gigafactory Berlin, which is expected to be equipped with the battery Tesla cars off the line at the end of August to early September at the earliest, while Tesla's Shanghai gigafactory has no plans to use BYD batteries.

teslamag.de confirmed the authenticity of the news. The Model Y with BYD batteries has reportedly received type approval from the EU, which was granted by the Dutch RDW (Dutch Ministry of Transport) on July 1, 2022. In the document, the new Model Y is referred to as Type 005, with a battery capacity of 55 kWh and a range of 440 km.

What are the advantages of blade batteries

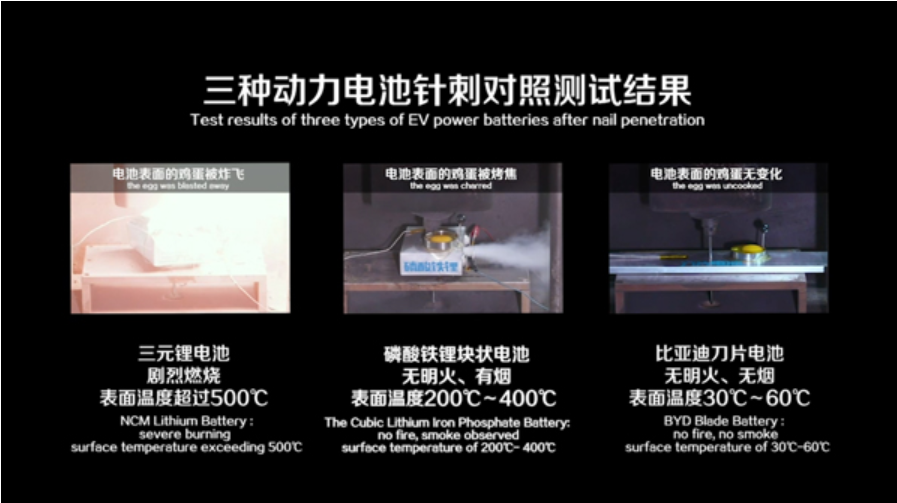

Safer: In recent years, electric vehicle safety accidents have been frequent, and the vast majority of them are caused by battery fires. The "blade battery" can be said to be the best safety in the market. According to BYD's published experiments on battery nail penetration test, we can see that "blade battery" after penetrating, battery temperature can also be maintained between 30-60 ℃, this is because the blade battery circuit is long, large surface area and fast heat dissipation. Ouyang Minggao, an academician of the Chinese Academy of Sciences, pointed out that the design of the blade battery makes it generate less heat and dissipate heat faster when short-circuiting, and evaluated its performance in the "nail penetration test" as excellent.

High energy density: Compared to ternary lithium batteries, lithium iron phosphate batteries are safer and have a longer cycle life, but previously in the battery energy density has been pressed head. Now the blade battery wh/kg density than the previous generation of batteries, although the 9% increase in wh/l energy density, but the increase of up to 50%. That is, the "blade battery" battery capacity can be increased by 50%.

Long battery life: According to experiments, the blade battery charging cycle life exceeds 4500 times, i.e. the battery decay is less than 20% after 4500 times charging, the life is more than 3 times of ternary lithium battery, and the equivalent mileage life of the blade battery can exceed 1.2 million km.

How to do a good job on the surface of the core shell, cooling plate, upper and lower cover, tray, baffle and other components to achieve the safety requirements of insulation, heat insulation, flame retardant, fireproof and meet the requirements of automated production? It is the major challenge and responsibility of the coating factory in the new period.

Post time: Aug-18-2022