The emergence of the electrophoretic coating process is an electrophoretic coating process, which puts forward higher and higher requirements for the quality of vehicle products. The high safety, high environmental protection and diverse personality of vehicles determine the increasingly high requirements for the surface protection technology of fasteners. So, what are the application characteristics of electrophoretic coating?

Electrophoretic coating has the following characteristics:

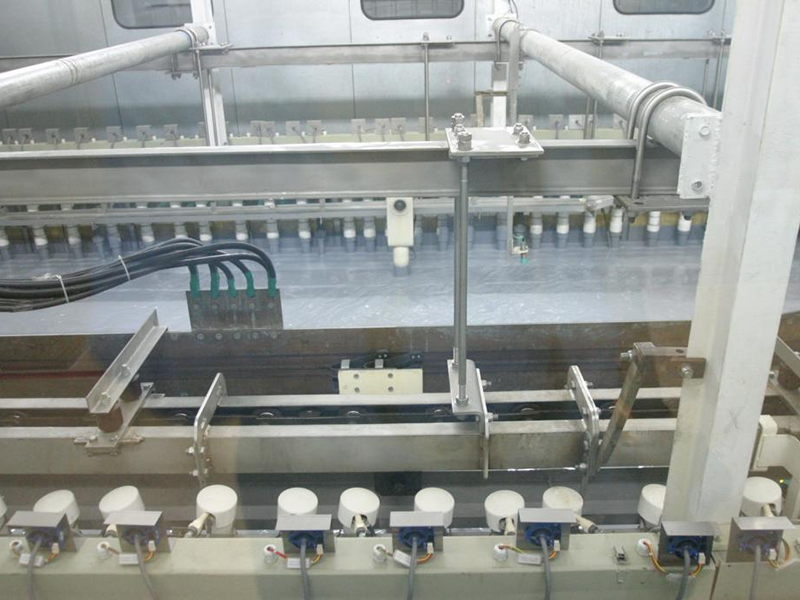

(1) The coating process is easy to mechanize and automate, which not only reduces labor intensity but also greatly improves labor productivity. With the development of the automobile industry, the technology and equipment of automobile coating, especially the automobile coating, have been rapidly applied in our country.

At present, the level of coating equipment installed in my country has been greatly improved. In the future, with the use of environmental protection coatings such as water-based coatings and powder coatings, my country's coating technology level will generally reach the world's advanced level. According to data from an automobile manufacturer, the efficiency of automobile primer has been increased by 450% after the original dip coating was changed to electrophoretic coating.

(2) Due to the electric field (J-N Y N), the electrophoretic coating has a complex shape, so it is suitable for workpieces with complex shapes, edges, corners, and holes, such as welded parts, etc., which can adjust the power and control the film thickness to a certain extent.

For example, in the crevices of the welding wires in place, the inner and outer surfaces of the box can get a relatively uniform paint film, and the resistance to corrosion and corrosion resistance is also significantly improved.

(3) The charged polymer particles are directionally deposited under the action of an electric field, so the water resistance of the electrophoretic coating film is very good, and the adhesion of the paint film is stronger than other methods.

(4) The paint liquid used in electrophoretic coating has low concentration and low viscosity, and the dipping action adheres to the coated workpiece, resulting in less paint loss. Paint can be put to good use. Especially after ultrafiltration technology is applied to electrophoresis, the interest rate of paint is above 95%.

(5) DI water is used as a solvent in electrophoretic paint (property: transparent, colorless liquid), which saves a lot of organic solvents, and there is no danger of solvent poisoning and flammability, which fundamentally eliminates paint fog and improves the working conditions of workers. and environmental pollution.

(6) Improve the flatness of the paint film, reduce the polishing time and reduce the cost.

Due to the above advantages of electrophoretic coating, it is currently widely used, such as automobiles, tractors, household appliances, electrical appliances, electronic parts and so on.

In addition, the appearance of color cathodic electrophoretic paint is suitable for the coating of various metals and alloys, such as copper, silver, gold, tin, zinc alloy (Zn), stainless steel, etc. Therefore, aluminum doors and windows, artificial jewelry, lighting, etc. have been widely used. Some surface treatment of black electrophoresis is to eliminate the adhesion of the coating film and the surface of the coated part, and to clean up the elements that affect these two links.

Post time: Jul-08-2022