Surley is a collection of pretreatment and electrophoresis processes Spray booth oven conveying system shower test bench environmental protection technology Accessories workstationstyle all in one store.

Hot New Products Hand Held Spray Gun - Pretreatment and electrocoating process – Surley

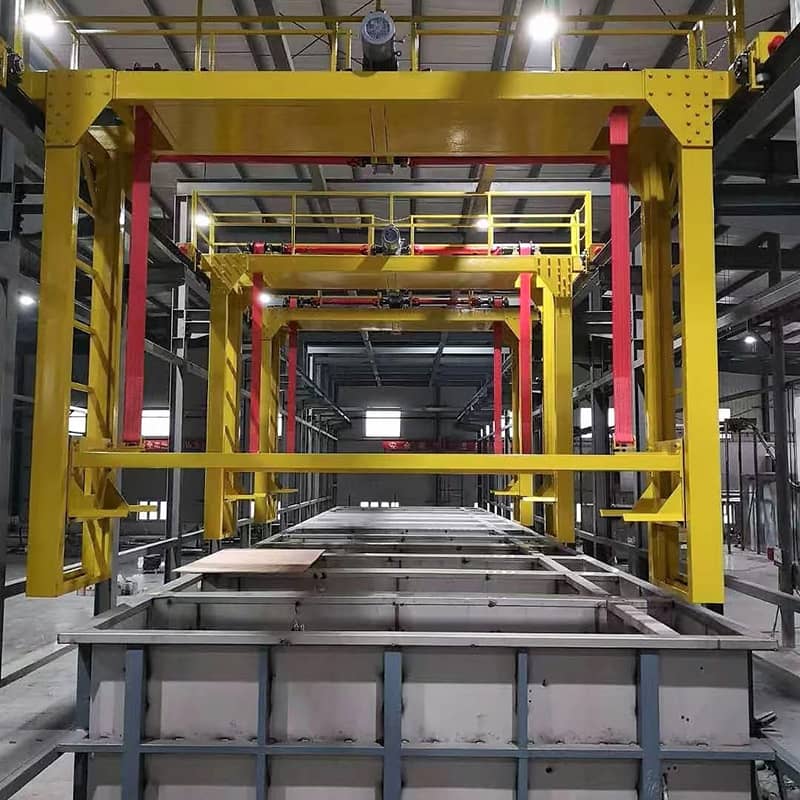

Hot New Products Hand Held Spray Gun - Pretreatment and electrocoating process – Surley Detail:

Product Description

Various materials and their products in the process of processing, transportation, storage, its surface is easy to produce or

stick foreign matter, such as machining burr, oxide skin, oil, etc., these surface contaminants will affect the compactness of the coating and the bonding strength with the matrix. Coating pretreatment of the mainThe objective is to remove these substances and perform the appropriate surface chemical conversion to provide suitableCoating requirements of the substrate, in order to increase the adhesion of the film, prolong the service life of the film, Give full play to the protective effect and decorative effect of coating.

Therefore, spray the content before processing. It mainly includes the following aspects:

Degreasing before coating

Steel and its parts in the process of storage and transportation to use antirust oil protection, sheet metal workpiece in drawing oil should be used when pressure processing, parts should contact emulsion when machining, heat treatment may contact cooling oil, when parts are often have oil stains and HanJi of the operator’s hands, the grease of the parts but also the impurities such as always and dust mixed together All this, all kinds of oil on the parts not only hinder the formation of phosphating film, but also affect the adhesion of the coating drying performance decorative performance and corrosion resistance Table 3-1 lists the different pretreatment of cold rolled steel plate. Effect of cathodic electrophoretic coating on corrosion resistance.

Phosphating

Phosphating is a simple, reliable, low-cost and convenient process to greatly improve the corrosion resistance of metal surface coating. It has been widely used at home and abroad, especially in automobile coating, which is more widely used in recent years. Almost 100% of the thin plate parts in the automobile industry are phosphating Phosphating process refers to the metal surface in contact with the acid solution containing dihydrogen phosphate salt, chemical reaction and generated in the metal surface stability of the insoluble inorganic compound membrane layer of a surface chemical treatment method and the generated film called phosphating film.

Phosphate film principle

phosphating film was able to provide a very appropriate base for paint coating, is due to the following effect :

1) Provides a clean, uniform, grease-free surface on the basis of complete degreasing

2) enhances the adhesion of organic film to the substrate due to physical and chemical action It is not difficult to understand that the porous structure of phosphating film increases the surface area of the substrate, so that the connection area between the two increases correspondingly, and the beneficial mutual permeability between the two film layers is generated. At the same time, the chemical interaction between unsaturated resin and phosphate crystal also enhances its binding force

3) provide a stable non-conductive isolation layer, once the coating damage, it has the role of corrosion inhibition, especially for anode incision The first point is often neglected Only to completely to the best of the oil to form a satisfactory phosphating film So the phosphating film itself is the most intuitive effect of pretreatment technology of the most reliable a self-check.

Product Details

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Hot New Products Hand Held Spray Gun - Pretreatment and electrocoating process – Surley , The product will supply to all over the world, such as: Switzerland, Sydney, Poland, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.