Surley is a collection of pretreatment and electrophoresis processes Spray booth oven conveying system shower test bench environmental protection technology Accessories workstationstyle all in one store.

Good Quality Environmental Technology - Environmental Technology Exhaust Gas Treatment – Surley

Good Quality Environmental Technology - Environmental Technology Exhaust Gas Treatment – Surley Detail:

Product Description

Exhaust gas treatment exhaust gas is harmful to human health and living environment, and the odor of the coating exhaust gas is mainly the solvent of the coating and the decomposition of the film when drying, they are mostly organic hydrocarbons. There are three types of air pollution in the exhaust gas from painting, namely

1) can become the organic solvent of photochemical smog < for example: xylene, methyl isobutyl ketone, isophorone, etc..

2) odorous paint volatiles, thermal decomposition products and reaction products (such as triethylamine, acrolein, formaldehyde, etc.)

3) paint spray dust.

Working Principle

1. The exhaust of the spray room in order to maintain the working environment of the spray room, the ventilation speed should be controlled within the range of (0.25 ~ 1) m/s according to the provisions of the Labor Safety and Health law. The exhaust of the general spray room is large air volume, the concentration of solvent vapor is very low (its volume fraction is roughly in the range of 10-3% ~ 2×10-’%). In addition, the exhaust of the spray room also contains part of the paint mist produced by spraying.

The particle size of this dust (lacquer fog droplets) is about (20 ~ 200) μm or so, no large wind flying far away, and cause a nearby public hazard, but also become an obstacle to waste gas treatment, these must be paid attention to.

2. The function of air drying room exhaust air in the room is to make the coating in the painting, drying or forced drying before, so that part of the solvent in the film smooth volatilization and the formation of a good film, generally is the extension of the painting room process, in this exhaust contains only solvent vapor, and almost no spray paint mist.

3. Exhaust from the drying room Exhaust gas discharged from the drying room, including exhaust from the paint system and fuel system. The former contains the residual solvent in the coating film not evaporated in the spray chamber and the drying chamber, part of the volatile components such as plasticizer or resin monomer, thermal decomposition products, reaction products. The latter is used as a heat source for fuel combustion exhaust gases. Its composition varies with fuel, such as burning heavy oil, containing a considerable amount of sulfur on the production of sulfite gas, when the furnace temperature is low, operation adjustment and poor maintenance and management, due to incomplete combustion and smoke. The use of gas fuel, although the fuel cost is high and the combustion exhaust gas is relatively clear, there are low equipment cost, easy maintenance, high thermal efficiency advantages. Where electricity and steam are used as heat sources in the drying room, exhaust gases from the fuel system are not considered.

Product Details

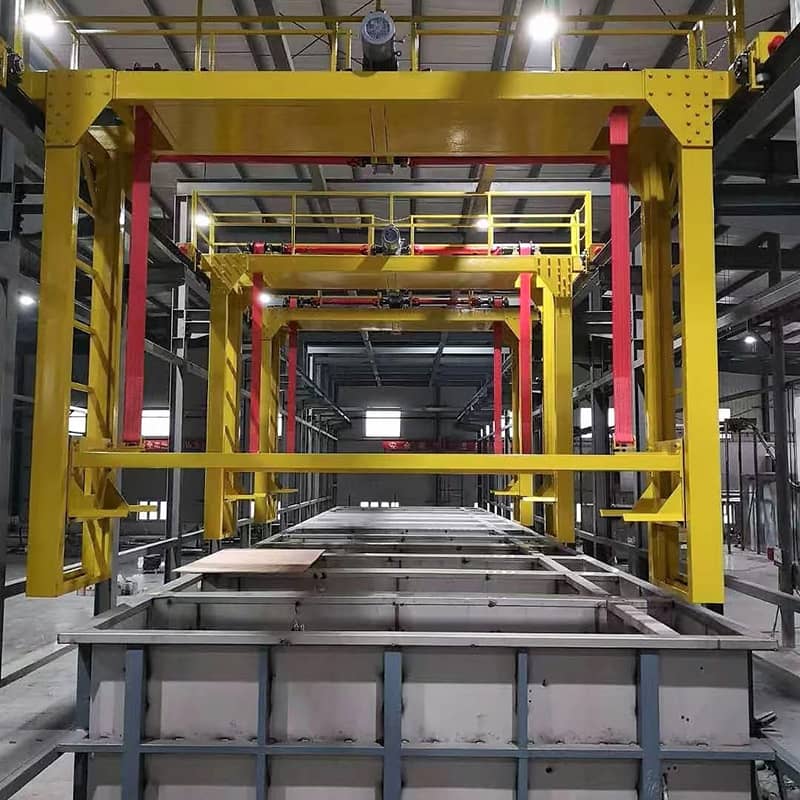

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Good Quality Environmental Technology - Environmental Technology Exhaust Gas Treatment – Surley , The product will supply to all over the world, such as: Liverpool, Dominica, Germany, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!