Surley is a collection of pretreatment and electrophoresis processes Spray booth oven conveying system shower test bench environmental protection technology Accessories workstationstyle all in one store.

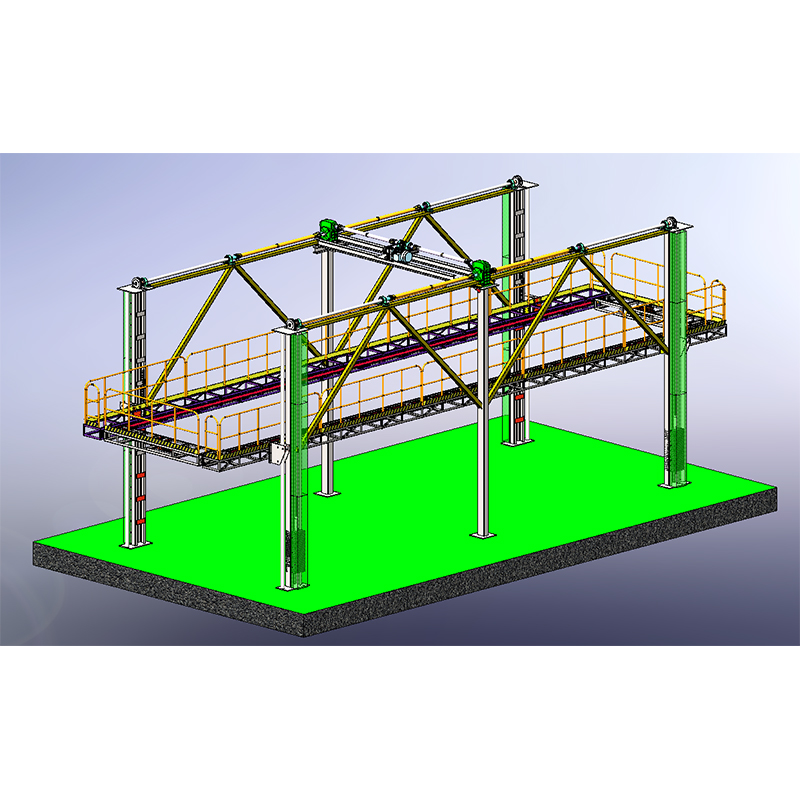

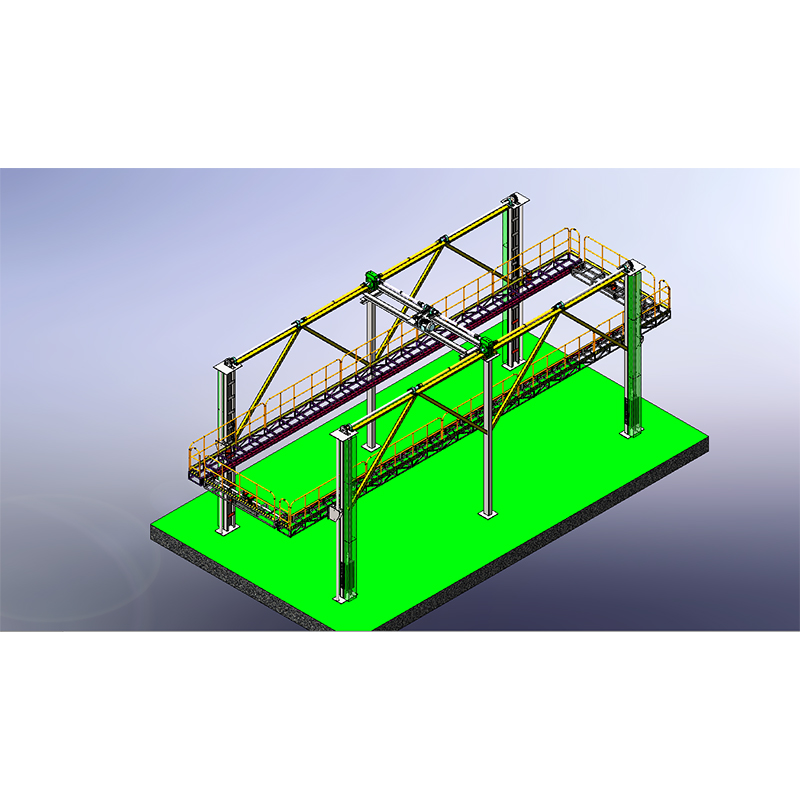

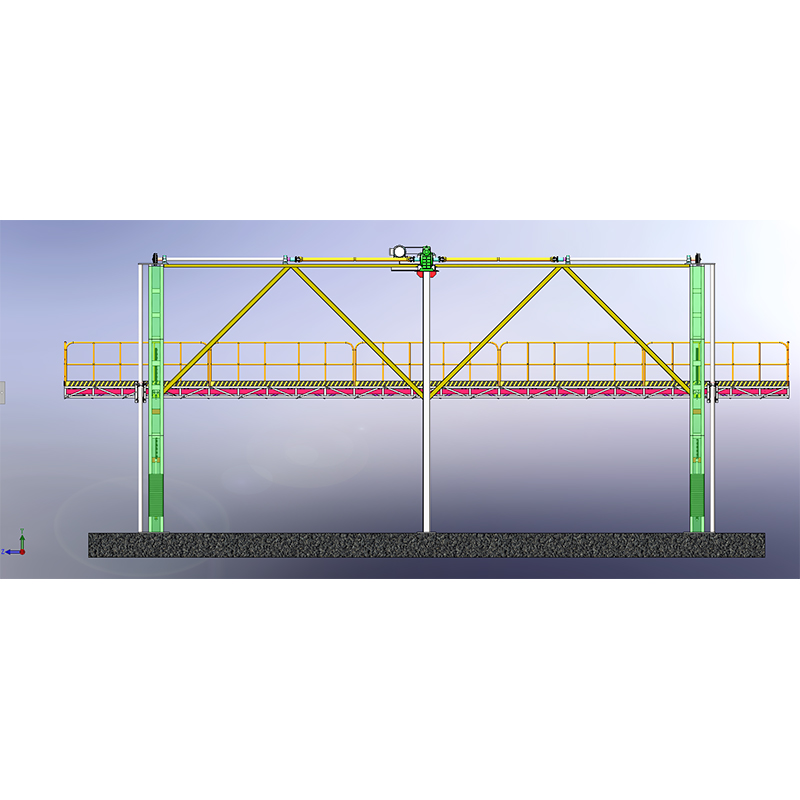

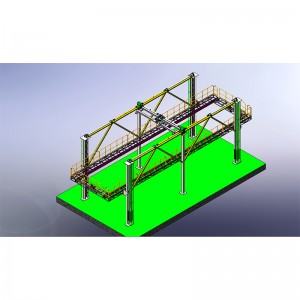

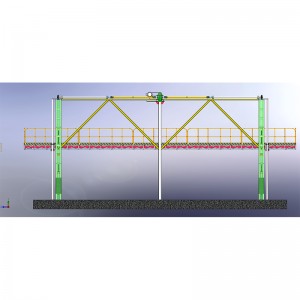

The Three-dimensional Lift Table

Product Description

There are three directions of movement, the first is the vertical and horizontal movement along the ground track, the second is the lifting movement up and down along the double column, and the third is the horizontal and horizontal telescopic movement perpendicular to the column, so as to achieve the three-dimensional movement requirements. The three-dimensional lift table produced by Jiangsu Suli Machinery Group Co., Ltd. has excellent quality and first-class after-sales service, and has won unanimous praise from customers.

Product Details